Machine Shop

-

Aviation Precise Machining

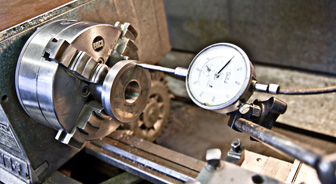

Canadian Aero Accessories (CAA) in-house machine shop is constantly turning, welding, balancing, and testing.

- Lathe: turning, resurfacing and manufacturing

- Balancing: components to minimize vibrations and wear

- Electroplating: filling and resurfacing

- Test Equipment: check for fit, finish and operation

Streamline Process

Overhauling and repairing aircraft parts require specialty services that include machining, CAA reduce wait times and ensure quality by performing the service internal.

Machining armatures to ensure reliable and safe contact is just the beginning of our service and testing in CAA machine shop. We check and adjust the balance of rotating accessories with the ability to test for the most rigorous of tolerances. Electroplating is available to ensure proper fit and finish on dynamic and static parts. CAA precision welder attaches and seals even the most delicate of accessories to manufacture specifications.

Repair tools

CAA custom builds precision tools and test equipment to meet the demands of our increasing list of aviation component overhaul and repair capabilities.

The Mechanical/Skydrol/Fuel shop tests and repairs a wide range of aircraft (fixed wing and helicopter) accessories that include Starter Generators, AC Generators, Generator Control Units, Boost Pumps, Fuel Pumps, , hydraulics 5606 and Skydrol, Landing gear, Brakes, and Actuators. Check CAA's extensive capabilities by part number.